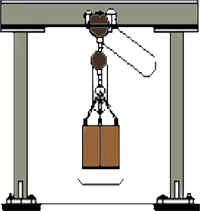

| This is for Suspended Electro-Magnetic Separator |

|

| The heart of all type of separators consists of one Powerful Electromagnet operating on Direct Current. The iron parts are made of high permeability mild steel and the parts are designed for most efficient magnetic field distribution and to produce maximum force density at a selected working distance from the magnet face. The bottom plate is made of heavy stainless steel plate. It is structurally rugged. The other design features include Class 'H' fiberglass insulated E. C. Grade Aluminum or in some cases Copper wound Coils, vacuum impregnated for higher operating strength and better heat dissipation. |

| |

|

|

|

|

Oil Cooled Magnets: |

|

|

|

The Oil Cooled Magnets are provided with External Oil Expansion Tank and the feature has helped the prevention of Coil Burning. Heat and moisture, the greatest enemies of electromagnets, are effectively controlled by the expansion tank, which assures that the coils are always completely immersed in cooling oil.

Competitive units provide space within the magnet housing where damaging condensation forms when moist air seeps in through the pressure relief valve as the magnet cools. The breather provided at the expansion tank traps the moisture and keeps it out of the magnet. Replaceable Stainless Steel Impact Plate to prevent damage to the magnet face. |

| |

|

|

|

| Model No |

|

L x W x H x C |

|

Lst. Wt. (KGs) |

|

Watts |

|

DC Volts |

|

| EMS 4242 |

|

42 X 42 X 22 X 56 |

|

2812 |

|

5.06 |

|

230VDS |

| EMS 4848 |

|

48 X 48 X 22 X 58 |

|

3221 |

|

6.02 |

|

230VDS |

| EMS 5454 |

|

54 x 54 x 22 x 62 |

|

4400 |

|

8.17 |

|

230VDS |

| EMS 6060 |

|

60 X 60 X 32 X 70 |

|

4944 |

|

12.47 |

|

230VDS |

|

|

| Other sizes available upon request |

|

| |

| Standard Features : |

| 1. Class H Aluminum Coils |

|

| 2. Heavy Duty Impact Plate |

|

| 3. Heavy Duty 4 Point Suspension |

|

| 4. Oil Expansion Tank |

|

| 5. Vacuum Wound Coils |

|

|

| Optional Features : |

| 1. Insulated Copper Coils |

|

| 2. DC Power Supplies |

|

| 3. Dust Proof Junction Box |

|

| 4. Water Proof Junction Box |

|

|

|

|

|

| |

|

|

|

|

Air Cooled Magnets: |

|

|

|

| The Air Cooled Magnets are provided with proper ventilation for free flow of air filters provided in certain cases. |

|

|

| |

|

| |

| |

| Sizes of Magnet |

|

Minimum |

|

Maximum |

|

|

|

|

| |

|

inch |

|

inch |

|

|

|

|

|

|

|

|

|

|

| Gap between magnet & Belt |

|

50 |

|

850 |

|

|

|

|

|

|

| |

|

Selection of a Electro-Magnetic Separator : |

|

| The most important factor in the selection of the proper size of a Magnet is burden depth, belt width, suspension position, size of tramp iron, speed of the belt, suspension height and type of the material carried by the Magnet. |

| |

| The following information is required to make the proper recommendation. |

|

|

Burden Depth |

|

|

|

Maximum Lump Size |

|

|

|

Belt Width |

|

|

|

Belt Speed |

|

|

|

|

|

|

|

|

|

Suspension position |

|

|

|

Degree of Troughing |

|

|

|

Tramp Iron Size (Max. & Min.) |

|

|

|

Idlers |

|

|

|

|

|

|

|

|

|

Material Size |

|

|

|

Belt Incline |

|

|

|

Capacity (TPH or CFH) |

|

|

|

Material Density |

|

|

|

|

|

|

|

|

|

Ambient Temperature |

|

|

|

Altitude |

|

|

|

Head Pulley Material |

|

|

|

Head Pulley Diameter |

|

|

|

|

|

|

|

|

|

Available Supply> |

|

|

|

|

|

|

|

|

| |

| Heavy Duty Suspended Magnetic Separator. |

| |

| |

It is economical to install and operate. This is a very basic equipment and as it has no moving parts, it is very sturdy.

Mount the unit at an angle over the material discharge point, or parallel to and above the conveyer line. There is no need to modify the existing conveyer installation.

The best position for the Magnet is at an angle over the conveyer head pulley, or at the discharge point of the feeder. Here the materials are loosening up and fanning out, thus the tramp iron literally leapes out and on the magnet face.In this position the magnet will more iron from deeper burdens from belts traveling at faster speeds. From the cost point of view, this installation provides the best tramp iron removal and at economical investment. They are an ideal choice where the contaminant iron content is low

The installations are made with the Magnet suspended parallel to and over the conveyer, where it is not feasible to locate the magnet at an angle over the discharging pulley. In this cases as the tramp iron must be pulled through a fairly sizable bed of material, it is usually necessary to install a larger and stronger Magnet. In either installation, discharge of accumulated tramp iron from the Magnet is fast and easy. Operator has to just move the magnet away from the conveyer, and turn off the current. The tramp iron will be dropped.

|

|

|

|

| * |

See Self Clean Suspended Magnetic Separator for easy self cleaning features. |

|

| |

|

|